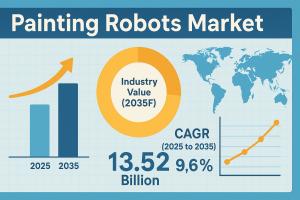

Painting Robots Market to Reach USD 13.52 Billion by 2035, Driven by AI Integration & Sustainability Push

Painting robots deliver uniform coatings, cut labor costs, reduce waste & support sustainability with AI precision, regulatory compliance & lower VOC emissions.

AI-powered painting robots are shaping a future where precision, sustainability, and automation coexist seamlessly in modern manufacturing.”

NEWARK, DE, UNITED STATES, June 17, 2025 /EINPresswire.com/ -- The global painting robots market is poised for robust expansion, projected to grow from USD 5.42 billion in 2025 to USD 13.52 billion by 2035, at a CAGR of 9.6%, according to a new market analysis. As industries embrace automation, the integration of AI-driven robotics and sustainable coating technologies is transforming the traditional painting landscape across automotive, aerospace, and general manufacturing sectors.— opines Nikhil Kaitwade, Associate Vice President at FMI

Painting robots are gaining traction due to their ability to offer uniform coating, reduced labor dependency, and precise paint application, helping industries achieve lower material wastage and enhanced finish quality. With real-time defect detection and intelligent path optimization powered by AI, these robots are aligning perfectly with evolving manufacturing standards that prioritize speed, quality, and compliance.

As regulatory frameworks tighten around emissions and hazardous waste, industries are turning to eco-friendly robotic painting solutions to maintain operational compliance while meeting sustainability targets. These next-gen robots significantly cut down volatile organic compounds (VOCs) and overspray, contributing to cleaner operations and resource conservation.

From automotive body painting to consumer electronics coating and aircraft part finishing, robotic painting solutions are now a staple in high-precision manufacturing environments. Their versatility, speed, and consistency make them indispensable for companies aiming to improve productivity and reduce cycle times without compromising quality.

𝗚𝗮𝗶𝗻 𝗩𝗮𝗹𝘂𝗮𝗯𝗹𝗲 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 𝗳𝗿𝗼𝗺 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗘𝘅𝗽𝗲𝗿𝘁𝘀 𝘁𝗼 𝗦𝗵𝗮𝗽𝗲 𝗬𝗼𝘂𝗿 𝗚𝗿𝗼𝘄𝘁𝗵 𝗦𝘁𝗿𝗮𝘁𝗲𝗴𝗶𝗲𝘀. 𝗔𝗰𝗰𝗲𝘀𝘀 𝗼𝘂𝗿 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁 𝗡𝗼𝘄: https://www.futuremarketinsights.com/reports/sample/rep-gb-7128

𝗥𝗲𝗽𝗼𝗿𝘁 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 & 𝗗𝗲𝗹𝗶𝘃𝗲𝗿𝗮𝗯𝗹𝗲𝘀:

This in-depth research report offers comprehensive coverage of:

- Market size projections (2025–2035)

- Regional trends and growth hotspots

- End-user demand analysis

- Competitive landscape and company profiles

- Technology innovations and sustainability trends

- Barriers to adoption and mitigation strategies

𝗞𝗲𝘆 𝗙𝗮𝗰𝘁𝗼𝗿𝘀 𝗦𝗵𝗮𝗽𝗶𝗻𝗴 𝗠𝗮𝗿𝗸𝗲𝘁 𝗗𝘆𝗻𝗮𝗺𝗶𝗰𝘀:

The rise in demand for precision, consistency, and compliance in coating applications, combined with advancements in AI robotics, is revolutionizing the market. These factors are making robotic painting systems a strategic investment for forward-thinking manufacturers.

𝗛𝗶𝗴𝗵 𝗜𝗻𝗶𝘁𝗶𝗮𝗹 𝗜𝗻𝘃𝗲𝘀𝘁𝗺𝗲𝗻𝘁 & 𝗜𝗻𝘁𝗲𝗴𝗿𝗮𝘁𝗶𝗼𝗻 𝗖𝗼𝘀𝘁𝘀:

Despite strong benefits, high upfront costs and system integration challenges remain barriers for SMEs. Initial capital requirements include advanced sensors, programmable robotic arms, and specialized software.

Further, integrating these systems with existing production lines often requires process reengineering and workforce upskilling, deterring quick adoption for cost-sensitive businesses.

𝗖𝗼𝗺𝗽𝗹𝗲𝘅 𝗠𝗮𝗶𝗻𝘁𝗲𝗻𝗮𝗻𝗰𝗲 & 𝗧𝗲𝗰𝗵𝗻𝗶𝗰𝗮𝗹 𝗟𝗶𝗺𝗶𝘁𝗮𝘁𝗶𝗼𝗻𝘀:

Robotic painting systems require frequent calibration, cleaning, and system updates to maintain performance accuracy. Their advanced components, such as atomizers and servo drives, demand specialized maintenance skills.

In addition, painting robots may face technical limitations when dealing with complex shapes or fragile surfaces, making them less effective in certain niche applications.

𝗔𝗜 & 𝗠𝗮𝗰𝗵𝗶𝗻𝗲 𝗟𝗲𝗮𝗿𝗻𝗶𝗻𝗴 𝗜𝗻𝘁𝗲𝗴𝗿𝗮𝘁𝗶𝗼𝗻:

AI and machine learning are playing a transformative role by enabling self-learning robots that adapt to object shapes, optimize spray angles, and identify defects in real time. These smart systems significantly improve operational uptime and finish consistency.

Moreover, predictive maintenance capabilities, guided by ML algorithms, allow operators to detect wear and tear before it disrupts operations, further maximizing return on investment.

𝗕𝗿𝗼𝘄𝘀𝗲 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗛𝗲𝗿𝗲: https://www.futuremarketinsights.com/reports/painting-robots-market

𝗞𝗲𝘆 𝗧𝗮𝗸𝗲𝗮𝘄𝗮𝘆𝘀:

Painting robots are rapidly evolving to meet the twin goals of operational efficiency and environmental responsibility. From achieving perfect coat thickness to cutting VOC emissions, these systems are now vital in global production environments. Their rising deployment across multiple sectors indicates a growing preference for automation that aligns with sustainability goals and regulatory compliance.

𝗦𝘂𝘀𝘁𝗮𝗶𝗻𝗮𝗯𝗶𝗹𝗶𝘁𝘆 & 𝗘𝗰𝗼-𝗙𝗿𝗶𝗲𝗻𝗱𝗹𝘆 𝗖𝗼𝗮𝘁𝗶𝗻𝗴 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀:

The painting industry is seeing a significant shift toward eco-friendly coatings and water-based paint systems. Robotic systems are particularly effective at managing the precise application of such coatings, minimizing environmental impact.

Electrostatic painting technologies, when integrated with robots, ensure minimal overspray and maximum transfer efficiency, thereby reducing both material consumption and air pollution.

𝗛𝗶𝗴𝗵 𝗔𝗱𝗼𝗽𝘁𝗶𝗼𝗻 𝗶𝗻 𝗔𝘂𝘁𝗼𝗺𝗼𝘁𝗶𝘃𝗲, 𝗖𝗼𝗻𝘀𝘂𝗺𝗲𝗿 𝗚𝗼𝗼𝗱𝘀 & 𝗛𝗲𝗮𝘃𝘆 𝗠𝗮𝗰𝗵𝗶𝗻𝗲𝗿𝘆:

The automotive industry continues to lead in robotic painting deployment due to high throughput needs and stringent quality norms. Robots allow manufacturers to maintain uniform color finishes while reducing cycle time.

In consumer goods and heavy machinery, painting robots help manage custom coatings, corrosion resistance layers, and aesthetic finishes, especially in mass production settings where speed and accuracy are non-negotiable.

𝗣𝗮𝗶𝗻𝘁𝗶𝗻𝗴 𝗥𝗼𝗯𝗼𝘁𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀:

- ABB Ltd. – A global leader in robotic automation, offering flexible painting robots with AI and vision systems.

- FANUC Corporation – Known for high-speed robotic arms used in automotive and electronics painting applications.

- Yaskawa Electric Corporation – Offers integrated paint robots with advanced path control and environmental protection features.

- KUKA AG – Provides intelligent robotic painting systems, focusing on automotive body and component coating.

- Kawasaki Heavy Industries, Ltd. – Specializes in customizable painting robots for varied industrial surfaces.

𝗜𝗻𝗶𝘁𝗶𝗮𝗹 𝗔𝗱𝗼𝗽𝘁𝗶𝗼𝗻 𝗼𝗳 𝗪𝗮𝘁𝗲𝗿-𝗕𝗮𝘀𝗲𝗱 𝗖𝗼𝗮𝘁𝗶𝗻𝗴𝘀 & 𝗘𝗹𝗲𝗰𝘁𝗿𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗧𝗲𝗰𝗵𝗻𝗶𝗾𝘂𝗲𝘀:

Early adopters of water-based coatings and electrostatic painting technologies have reported significant reductions in hazardous waste and VOC emissions. These methods, when deployed through robotic systems, enhance coating uniformity while being environmentally sound.

As sustainability regulations tighten, industries are moving toward closed-loop systems with electrostatic capabilities, helping reduce both material costs and energy consumption.

𝗥𝗲𝗴𝗶𝗼𝗻𝗮𝗹 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀:

- North America: Leading in AI integration and smart factories, especially in automotive and aerospace.

- Latin America: Growing adoption in automotive assembly lines and consumer goods.

- Western Europe: Strong push for sustainable manufacturing, favoring eco-friendly robotic solutions.

- Eastern Europe: Increasing investment in automation by manufacturing hubs.

- East Asia: Dominates in robotic deployment, particularly China, Japan, and South Korea.

- South Asia & Pacific: Rapid industrialization and supportive government initiatives driving growth.

- Middle East & Africa: Slow but steady adoption in oil & gas-related coatings and heavy equipment manufacturing.

𝗟𝗮𝘁𝗲𝘀𝘁 𝗛𝗲𝗮𝘃𝘆 𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗥𝗲𝗽𝗼𝗿𝘁𝘀: https://www.futuremarketinsights.com/industry-analysis/heavy-engineering-solutions

𝗠𝗮𝗿𝗸𝗲𝘁 𝗦𝗲𝗴𝗺𝗲𝗻𝘁𝗮𝘁𝗶𝗼𝗻

By Type:

- Pedestal Robots

- Robotic Arms

By Application:

- Atomizer

- Air Gun

By End Use Sector:

- Transportation

- Consumer Appliances

- Foundry & casting

- Furniture

- Textiles

- Construction

- Heavy Engineering Equipment

- HVAC & Refrigeration

- Sanitaryware

- Others

𝗘𝘅𝗽𝗹𝗼𝗿𝗲 𝗙𝗠𝗜’𝘀 𝗘𝘅𝘁𝗲𝗻𝘀𝗶𝘃𝗲 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 𝗼𝗻 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗗𝗼𝗺𝗮𝗶𝗻:

The industrial security system market is expected to grow at a CAGR of 7.5% during the projected period. The market value is expected to increase from USD 55.9 billion in 2024 to USD 115 billion by 2034.

The gasket and seal market is projected to be valued at USD 87,012.9 million in 2024 and rise to USD 152,911.56 million by 2034. It is expected to grow at a CAGR of 2.10 %

𝗔𝗯𝗼𝘂𝘁 𝗙𝘂𝘁𝘂𝗿𝗲 𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 (𝗙𝗠𝗜)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai and has delivery centers in the United Kingdom, the United States, and India. FMI's latest market research reports and industry analysis helps businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert-led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝗖𝗼𝗻𝘁𝗮𝗰𝘁 𝗨𝘀:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights, Inc.

+ +91 90966 84197

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.