Global Rotary Screw Compressor Market Size to Reach USD 6.97 Billion by 2034, Growing at 4% CAGR

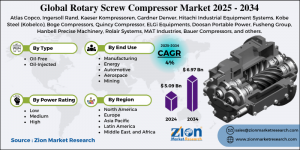

The global rotary screw compressor market size was approximately USD 5.09 billion in 2024 and is projected to reach around USD 6.97 billion by 2034

The global rotary screw compressor market size was approximately USD 5.09 billion in 2024 and is projected to reach around USD 6.97 billion by 2034, (CAGR) of roughly 4% between 2025 and 2034.”

PUNE, MAHARASHTRA, INDIA, September 10, 2025 /EINPresswire.com/ -- The global rotary screw compressor market Size represents a critical segment within the industrial machinery and equipment sector, providing essential compressed air solutions across a vast array of industries. With an estimated valuation of USD 5.09 billion in 2024, the market demonstrates stable and consistent growth, projected to reach USD 6.97 billion by 2034. This expansion is expected to occur at a Compound Annual Growth Rate (CAGR of approximately 4% during the forecast period from 2025 to 2034. This growth is underpinned by relentless industrialization, the imperative for energy-efficient industrial equipment, and the modernization of manufacturing infrastructure. However, the market faces headwinds from initial high capital costs and the maturity of key end-user sectors in developed regions.— Deepak Rupnar

Access key findings and insights from our Report in this Free sample -https://www.zionmarketresearch.com/sample/rotary-screw-compressor-market

This report provides a granular analysis of the market, dissecting it by product type, stage, technology, application, end-user industry, and geography. It further offers a detailed competitive landscape profiling the key players, their strategic initiatives, and market positioning. The insights herein are designed to equip OEMs, suppliers, investors, and end-users with the intelligence needed to navigate market opportunities and challenges in the coming decade.

1. Introduction and Market Definition

A rotary screw compressor is a type of gas compressor that uses a rotary-type positive-displacement mechanism. Two intermeshing helical screws, known as rotors, are used to compress the air. Known for their reliability, continuous operation capability, and efficiency in medium to high power applications, they have become the industrial workhorse for compressed air, displacing older, less efficient technologies like reciprocating compressors in many applications.

This report defines the market based on the sales revenue of rotary screw compressors, including both oil-injected and oil-free variants, across various power ratings and configurations. The scope is global, encompassing major regional markets and their unique demand dynamics.

Key Insights:

As per the analysis shared by our research analyst, the global rotary screw compressor market is estimated to grow annually at a CAGR of around 4% over the forecast period (2025-2034)

In terms of revenue, the global rotary screw compressor market size was valued at around USD 5.09 billion in 2024 and is projected to reach USD 6.97 billion by 2034.

The rotary screw compressor market is projected to grow significantly due to the growth in industrial manufacturing activities, the surging adoption in the food and beverage sector, and government regulations for energy conservation.

Based on type, the oil-injected segment is expected to lead the market, while the oil-free segment is expected to grow considerably.

Based on power rating, the medium is the dominant segment, while the low segment is projected to witness sizable revenue growth over the forecast period.

Based on end use, the manufacturing segment is expected to lead the market compared to the energy segment.

Based on region, Asia Pacific is projected to dominate the global market during the estimated period, followed by Europe.

Do You Have Any Query Or Specific Requirement? Request Customization of Report:https://www.zionmarketresearch.com/custom/9707

2. Market Dynamics: Drivers, Restraints, and Opportunities

2.1. Market Drivers

Industrialization and Manufacturing Growth: The ongoing industrialization in emerging economies across Asia-Pacific, Latin America, and Africa is a primary driver. The establishment of new manufacturing facilities directly fuels demand for reliable compressed air sources.

Stringent Energy Efficiency Regulations: Governments and environmental agencies worldwide are implementing strict regulations to reduce energy consumption. Rotary screw compressors, especially variable speed drive (VSD) models, offer significant energy savings compared to fixed-speed alternatives, driving their adoption.

Replacement of Aging Compressor Fleet: In mature markets, a significant opportunity lies in the replacement of old, inefficient reciprocating and fixed-speed screw compressors with new, energy-efficient rotary screw models to reduce operational expenses (OPEX).

Growth in End-Use Industries: Key sectors such as food & beverage (for packaging and processing), pharmaceuticals (for process air), electronics (for component actuation), and automotive (for painting and tools) are consistently growing, directly propelling market demand.

Low Maintenance and Operational Reliability: The design of screw compressors allows for 24/7 operation with lower maintenance requirements than reciprocating compressors, reducing downtime and total cost of ownership, a key factor for industrial users.

2.2. Market Restraints

High Initial Capital Investment: The upfront cost of a rotary screw compressor, particularly oil-free and VSD models, is significantly higher than that of traditional compressor technologies. This can be a barrier for small and medium-sized enterprises (SMEs).

Market Maturity in Developed Regions: Markets in North America and Western Europe are relatively mature, with growth primarily driven by replacement sales rather than new installations, potentially limiting high growth rates.

Economic Cyclicality and Capital Expenditure Sensitivity: The market is tied to industrial capital expenditure (CAPEX). Economic slowdowns, recessions, or uncertainties can cause manufacturers to delay or cancel investments in new equipment.

2.3. Market Opportunities

Rise of Industry 4.0 and Smart Compressors: The integration of IoT sensors, connectivity, and data analytics allows for predictive maintenance, remote monitoring, and optimized energy usage. Offering smart, connected compressors is a key differentiator and a high-growth niche.

Expansion in Emerging Economies: Countries in Southeast Asia (e.g., Vietnam, Indonesia), India, and parts of Latin America present immense growth opportunities due to new factory setups, foreign direct investment, and government initiatives like "Make in India."

Focus on Oil-Free Technology: Growing demand from critical applications in food & beverage, pharmaceuticals, and electronics where air purity is paramount is driving the faster-growing segment of oil-free screw compressors.

Rental and Service-Based Models: Developing strong aftermarket services, long-term service agreements, and compressor rental fleets provides a recurring revenue stream and builds customer loyalty beyond the initial sale.

3. Market Segmentation Analysis

The global rotary screw compressor market is segmented to understand the diverse product offerings and applications.

3.1. By Product Type

Stationary Screw Compressors: The dominant segment in terms of revenue. Used in fixed industrial settings like manufacturing plants, workshops, and large facilities where compressed air is required continuously at a central location.

Portable Screw Compressors: Used in applications requiring mobility, such as construction, mining, and oil & gas fields. Their growth is tied to infrastructure development and energy sector projects.

3.2. By Stage

Single-Stage Screw Compressors: Simpler design, cost-effective for applications requiring pressures up to 150 psi. Common in general manufacturing and automotive shops.

Multi-Stage Screw Compressors: Used for higher pressure applications (above 150 psi). They offer higher efficiency for high-pressure needs but come at a higher cost. Used in specific industries like PET bottling and energy.

3.3. By Technology

Oil-Injected Screw Compressors: The larger segment by volume. Oil is used to cool, lubricate, and seal the compressor elements. Suitable for most industrial applications where minor oil carry-over is not an issue (e.g., general manufacturing, assembly lines).

Oil-Free Screw Compressors: A premium, faster-growing segment. Use specially coated rotors and operate without oil in the compression chamber, delivering 100% oil-free air. Essential for critical applications in food, pharma, semiconductors, and textiles.

3.4. By Application

Air Compression: The universal application for providing plant air for tools, machinery, and processes.

Gas Compression: Used for compressing other gases like nitrogen, natural gas, or biogas in specific industrial processes.

3.5. By End-User Industry

Manufacturing: The largest end-user segment, encompassing automotive, machinery, plastics, and metal fabrication.

Food & Beverage: A high-growth sector due to strict hygiene standards, driving demand for oil-free compressors for mixing, packaging, and cleaning.

Oil & Gas: Used in upstream, midstream, and downstream operations for gas compression, instrumentation, and process air.

Healthcare & Pharmaceuticals: Requires completely oil-free, sterile air for manufacturing processes and instrument air, making it a key market for high-end oil-free compressors.

Construction & Mining: Primarily utilizes portable screw compressors to power pneumatic tools, drills, and equipment on-site.

Others: Includes textiles, electronics, power generation, and chemicals.

4. Regional Analysis

The market landscape exhibits distinct characteristics across different geographies.

Asia-Pacific (APAC):

Market Character: The largest and fastest-growing regional market. Driven by China, India, Japan, and South Korea.

Growth Drivers: Massive manufacturing base, rapid industrialization, favorable government policies promoting FDI, and infrastructure development. China is both a major consumer and the world's largest manufacturer of compressors.

Challenges: Intense price competition from local manufacturers and economic fluctuations.

North America:

Market Character: A mature and technologically advanced market, led by the U.S.

Growth Drivers: Replacement demand for energy-efficient models, strong presence of key end-user industries (automotive, aerospace, food & beverage), and high adoption of Industry 4.0 technologies.

Challenges: Market maturity limits high volume growth, making it a value-driven market.

Europe:

Market Character: A mature market with a strong focus on energy efficiency and environmental sustainability. Germany, Italy, and France are key contributors.

Growth Drivers: Stringent EU energy efficiency regulations (e.g., ErP Directive), a strong manufacturing sector (especially machinery and automotive), and high demand for oil-free compressors in the food and pharmaceutical industries.

Challenges: Economic fragility in some regions and high market penetration.

Latin America, Middle East, and Africa (LAMEA):

Market Character: An emerging market with growth potential, though uneven. Growth hotspots include GCC countries (oil & gas sector) and Brazil.

Growth Drivers: Infrastructure projects, mining activities, and investments in the oil & gas sector.

Challenges: Political and economic instability in some countries can hinder consistent investment.

Inquiry For Buying-https://www.zionmarketresearch.com/inquiry/rotary-screw-compressor-market

5. Key Player Landscape and Competitive Analysis

The market is highly competitive and fragmented, with the presence of global giants, regional players, and numerous local manufacturers, especially in Asia. Competition is based on product performance, energy efficiency, price, service network, and technological innovation.

The key operating players in the global rotary screw compressor market are:

Atlas Copco

Ingersoll Rand

Kaeser Kompressoren

Gardner Denver

Hitachi Industrial Equipment Systems

Kobe Steel (Kobelco)

Boge Compressors

Quincy Compressor

ELGi Equipments

Doosan Portable Power

Fusheng Group

Hanbell Precise Machinery

Rolair Systems

MAT Industries

Bauer Compressors

Other Notable Players: Gardner Denver (now part of Ingersoll Rand), Siemens Energy (contributing to the oil-free segment), ELGi Equipments Limited (a major Indian player with strong global exports), Chicago Pneumatic (part of Atlas Copco), and Quincy Compressor (part of Atlas Copco).

6. Strategic Recommendations

For Established Players: Intensify R&D focus on smart, IoT-enabled compressors and energy-efficient VSD technology. Develop strong lifecycle service contracts and rental offerings to ensure recurring revenue. Target high-growth end-user industries like food & beverage and pharmaceuticals with tailored solutions.

For New Entrants: Identify and serve niche applications or specific geographic regions underserved by giants. Consider a component supplier role or forming partnerships with larger OEMs. Focus on cost-competitive, reliable solutions for the price-sensitive SME segment.

For Investors: The oil-free compressor segment and companies with strong IoT and predictive maintenance capabilities present attractive investment opportunities due to their higher growth and margins. Monitoring the competitive landscape in high-growth APAC markets is also advised.

7. Conclusion

The global rotary screw compressor market, while mature, is far from stagnant. The projected steady growth to USD 6.97 billion by 2034 is a testament to its indispensable role in modern industry. The future of this market will be defined not by volume alone, but by value—specifically, the value of energy savings, air purity, data-driven insights, and operational reliability. Success will belong to those manufacturers who can evolve from being equipment suppliers to becoming providers of comprehensive, efficient, and connected air solutions. The transition towards energy efficiency, digitalization, and emerging economies will be the key levers for growth in the coming decade.

Browse Other Related Research Reports from Zion Market Research-

Weaving Machines for Heavy Technical Fabrics Market By Application (Chemical Fiber Industry and Natural Fiber Industry), By Type (Projectile Weaving Machines, Rapier Weaving Machines, Water-Jet Weaving Machines, Air-Jet Weaving Machines, and Multi-Shed Weaving Machines), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/weaving-machines-heavy-technical-fabrics-market

Wafer Stick Machine Market By Type (Fully Automatic and Semi-Automatic), By Application (Food Production and Food Processing), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/wafer-stick-machine-market

Forklift Seats Market Analysis By Application (Container Forklifts and Small Lift Trucks), By Type (Air Suspension Seat and Mechanical Suspension Seat), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/forklift-seats-market

Industrial Air Cannon Market By Application (Industrial and Construction), By Type (Typhoon Air Cannon and Hurricane Air Cannon), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/industrial-air-cannon-market

Vibratory Tubs Market Analysis By Type (Stand-alone Unit and Continuous Device), By Application (Automotive, Aerospace, Medical Industry, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/vibratory-tubs-market

Powered Industrial Trucks Market By Type (Weight: <5 Ton, Weight: 5-10 Ton, Weight: 10-30 Ton, and Weight: >30 Ton), By Application (Warehousing, Manufacturing, Freight & Logistics, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-https://www.zionmarketresearch.com/report/powered-industrial-trucks-market

Deepak Rupnar

Zion Market Research

+1 855-465-4651

richard@zionmarketresearch.com

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.